Wheel impact test

In order to achieve better performance and quality, the wheel design and manufacturing use a number of wheel tests (rotating bending test, radial fatigue test, and impact test) to insure that the wheel meets the safety requirements. The test is very time consuming and expensive. Computer simulation of these tests can significantly reduce the time and cost required to perform a wheel design.

The wheel impact test evaluates wheel structural performance for a typical lateral curb impact event occurring in passenger cars and light trucks.

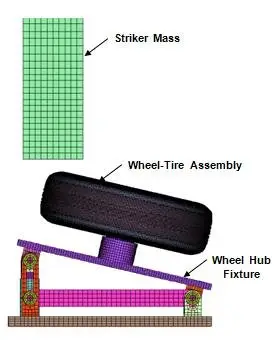

This test which is as per SAE J -175 standard has a striker dropped from a specified height on to a fixture mounted wheel-tire assembly. This impact test performance is critical to meeting overall structural performance for the wheel. There are many processes and methods available to simulate impact tests using FE analysis and FE analysis-test correlation is achieved within 3% (strain gauge measurements).

Methodology:

The test fixture used for the impact test consists of a striker with specified weight. The test is intended to simulate actual vehicle impact conditions. The tire-wheel assembly is mounted at 13° angle to the vertical plane with the edge of the weight in line with outer radius of the rim. The striker is dropped from a specified height above the highest point of the tire-wheel assembly and contacts the outboard flange of the wheel.

Result interpretation:

The prediction of a wheel failure at impact is based on the condition that fracture will occur if the maximum strain energy density of the wheel during the impact test exceeds the total plastic work of the wheel material from tensile test. The simulated results in this work show that the total plastic work can be effectively employed as a fracture criterion to predict a wheel fracture of forged aluminum wheel during impact test.