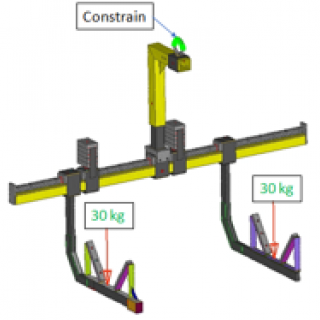

In today's world, there is a wide variety of material handling equipments, from the large heavy loading truck to the one that works among narrow aisles. These equipments have become one of the basic transportation tools we use in our lives. We find that there are some improvements that can be made to bring the forklifts, cranes, tackles, etc. to a better performance. Once the design is conceived, we calculate the mass properties of parts and subassemblies to ensure the stability of the lifting tackle and its supports.

Methodology:

There are variety of material models available for manufacturing such components. Some have good strength, properties and cost. But material should be available easily and have required properties in reliable cost, this will only reduce economic factor of the project. Mostly mild steel is selected as a parent material for structure of tackle. After selection of material, loads of pre-defined magnitude (specified by the customer) are applied at certain locations in order to check the sustainability and strength of welds, joints, bolts and supports. The analysis carried out is generally a static case.

Result interpretation:

The post-processing results include verification of loads and the stresses (Von-mises) generated at certain sections of structure, occurrence of deformation in the structure, Max stress values and weld failure. Ultimately, we conclude whether the equipment is safe for use or not by calculating the factor of safety from stress values obtained in post-processing.

The test results match with analysis results with 12% and 9.75% variation, but it may be due to environmental conditions, machining methods, imperfect shapes in real life product and due to point load application in real test while in software it is applied through bunch of nodes.